It all started with the "Horizont" plant ...

Founded in 1965 under the USSR Ministry of Electronic Industry, the plant (originally called "Horizon") was fully funded from the state budget and was conceived as a supplier of high-tech electromagnetic components for the aerospace and shipbuilding industry.

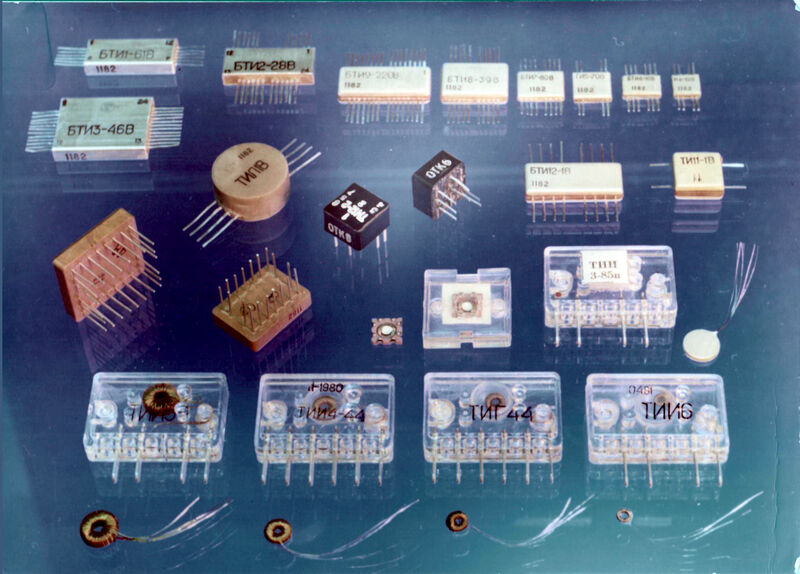

Horizont's compact production facilities were initially specialized in the production of high-frequency chokes.

Later, the company's product range was expanded with new products such as delay lines for television systems (early seventies) and pulse transformers (1975).

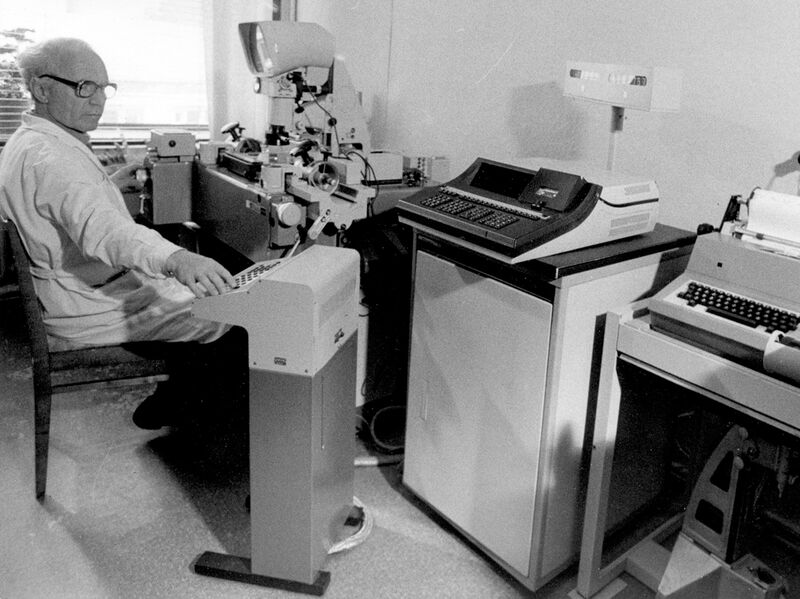

It is the compactness of the enterprise and the flexibility of its production process that have always allowed the enterprise to introduce the newest industrial technologies for its time.

The Horizont plant became the first enterprise that mastered the use of cores in microtransformers made of amorphous tapes with increased electromagnetic characteristics instead of permalloy. This entire series of magnetic cores is also the main product of the enterprise, supplied to Russian and foreign customers.

The production of pulse transformers has been mastered

Rejection of permalloy materials and transition to amorphous and nanocrystalline ribbons

First production

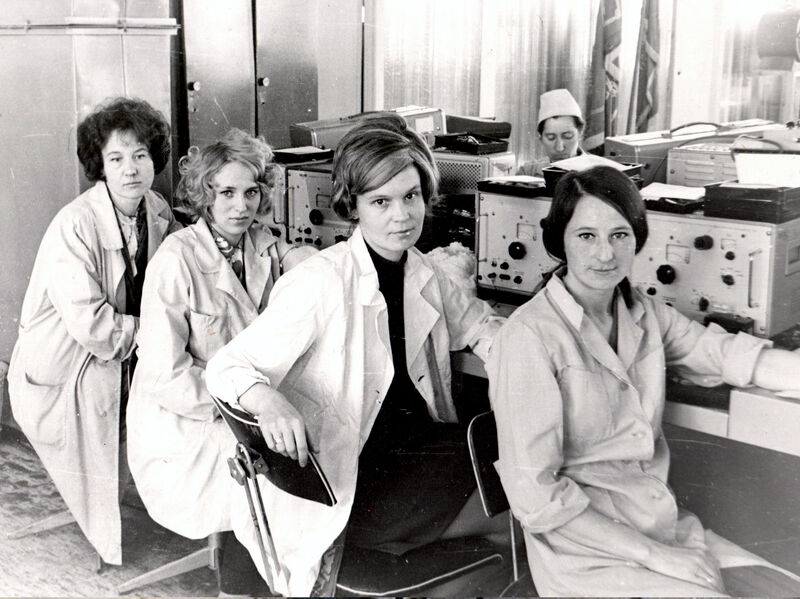

The cooperation of the plant with various relevant ministries and research institutes has led to the gradual accumulation of outstanding scientific potential at the enterprise.

It was this intellectual baggage that allowed Horizon to continue its development in the early nineties, when all Soviet enterprises of this kind found themselves without minimum budget funding against the backdrop of a collapsing planned economy and were forced to fight for survival by all means.

During this difficult period, the management of "Horizon", with varying success, attempted to bring the plant out of the crisis by mastering such less technologically advanced and more consumer-oriented products, such as magnetic readheads for audio cassette players and power transformers for household appliances.

An even more important role was played by the fact that the scientific base of "Horizon" functioned at that time, despite financial difficulties.

It was in the first half of the nineties that unique equipment was developed at the plant's research center - machines for filling, cutting and annealing amorphous magnetic tape.

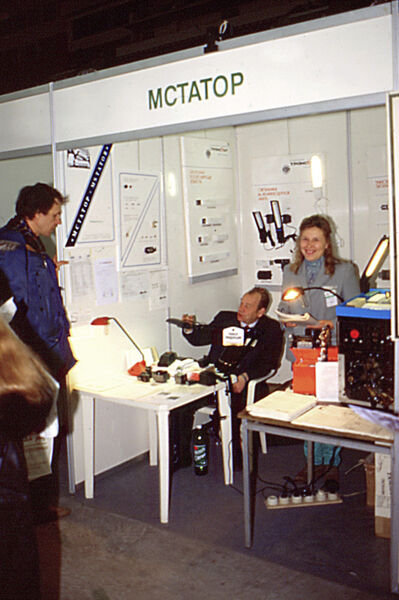

This equipment not only made it possible to significantly streamline the production process at the plant itself, but also began to be offered for sale. At the same time, the plant was privatized and became known as MSTATOR.

The plant "MSTATOR" became the legal successor

The compactness of the enterprise and the flexibility of its production process have always allowed the enterprise to introduce the latest industrial technologies for its time. The cooperation of the plant with various relevant ministries and research institutes has led to the gradual accumulation of outstanding scientific potential at the enterprise.

It was this intellectual baggage that allowed Horizont under the new name MSTATOR to continue its existence in the early nineties, when all Soviet enterprises of this kind found themselves without minimum budget funding against the backdrop of the collapsing planned economy and were forced to fight for survival by all means.

Facade of the MSTATOR plant

"MSTATOR" at the exhibition (1995)

Workshop No. 4 (2011)

In 1993, the plant's management established business contacts with South Korea, which made it possible to expand the range of products offered and attract a significant amount of foreign investment.

Until now, Asian partners (Amogreentech) maintain close business and friendly relations with the plant, striving to strengthen mutually beneficial cooperation with new orders for the Asian market. There are also regular deliveries to Germany, Poland, France, China, etc.

Exceptional importance is given to the miniaturization and unification of products. Since 2010, PC "MSTATOR" has mastered the serial production of micro-inductances, micro-chokes, chip inductors.

Development work has been completed and serial production of a miniature transformer module designed for information exchange channels (Ethernet) has been mastered.