Topic: Power supplies for communication systems and radio engineering

Report of the All-Russian Scientific and Practical Conference "Power Supply-2021" in V. Novgorod, dedicated to the 30th anniversary of the Association "Power Supply" - from 2 to 5 June 2021 at the Novgorod State University named after Yaroslav the Wise (Russia, Veliky Novgorod, Antonovo, 1)

Author: Fochenkov Eduard Anatolyevich, Head of the Bureau of Mechanization and Automation of PC “MSTATOR”, technical consultant on the use of magnetic materials and calculations of electromagnetic components.

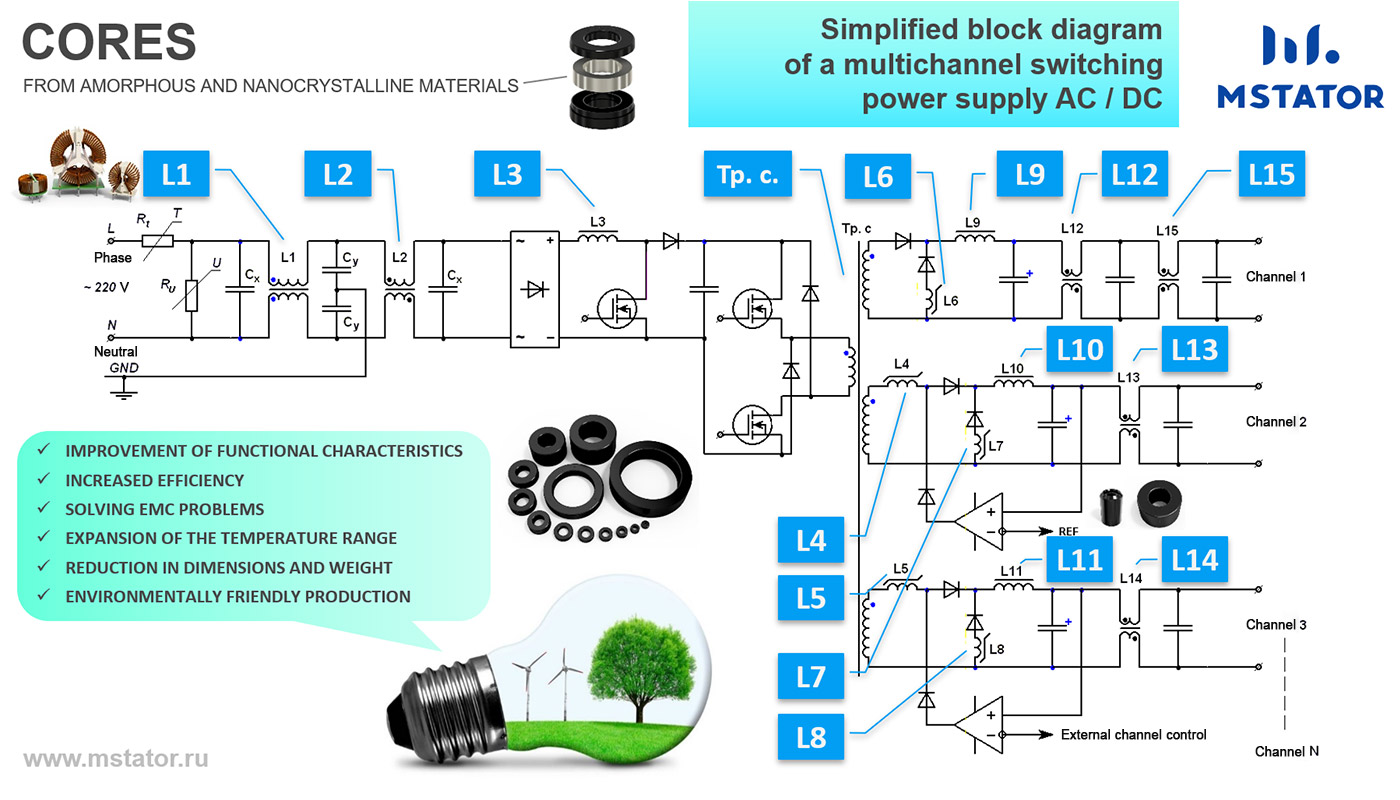

Abstract: The report examines the technical features and advantages of the soft magnetic materials and magnetic cores produced by PC “MSTATOR” (city of Borovichi) in relation to the field of switching power supplies. Recommendations are given on the choice of optimal materials and magnetic cores according to their purpose in the circuit using the example of a block diagram of an AC / DC multichannel power supply. Magnetic cores for common-mode interference suppression chokes, their distinctive features and problems arising in the implementation of interference suppression chokes and EMC filters are considered in more detail.

Introduction

PC «MSTATOR» is one of the leading enterprises in the Russian Federation in the field of amorphous and nanocrystalline soft magnetic materials. The enterprise has mastered and successfully develops the patented developments of the leading scientific center of the USSR - Kaluga Research Institute of Electronic Materials. It produces more than 20 types of alloys in the form of thin ribbons and complete electromagnetic components based on them. Has 55 years of experience in the production of electromagnetic components. Products are supplied to the foreign and domestic (including acceptance 5 and 9) markets. PC "MSTATOR" possesses unique technologies allowing to produce the thinnest (from 16 microns) ribbon in Russian Federation. The wide size range of toroidal magnetic cores from 3 mm to 200 mm in outer diameter. Wide range of magnetic permeability (from 210 to 300,000) and saturation flux density (from 0.55 to 1.4 T). Ability to operate in a wide temperature range from –60 to 300 ° С. The products of PC "MSTATOR" successfully compete with the products of the world's leading manufacturers - Vacuumschmelze, Magnetec, Hitachi, etc.

There is an opinion that modern amorphous and nanocrystalline alloys will gradually displace ferrites from the market. In fact, this opinion is erroneous. Each material has its own optimal area of application, in which the particular material gives the best result. In addition, the technical requirements for SMPS and operating conditions may be different. According to "LEPKOS" estimates, toroidal magnetic cores occupy less than 30% of the market, and this is the main form for amorphous and nanocrystalline materials. Ferrite has the advantage of low cost, so other materials are usually not worth using in inexpensive devices operating over a narrow temperature range. At the same time, amorphous and nanocrystalline alloys have a number of unique properties that are fundamentally unattainable for ferrite. Therefore, it would be correct to say that the proportion of amorphous and nanocrystalline materials is growing and will continue to grow in the future in specific applications, where these materials have a clear advantage over ferrites.

The purpose of this message is to show consumers what exactly can be expected from the use of new materials and which specific alloys are appropriate to use in each specific case. In addition, today domestic manufacturers have a number of problems that do not allow them to master analogues of the best imported ferrites and magneto dielectrics. And this creates problems with import substitution. The products of PC "MSTATOR" are included in the list of electronic components and in terms of their technical characteristics, as a rule, they are not inferior to the products of the world leaders in the field of amorphous and nanocrystalline materials. PC "MSTATOR" has been supplying magnetic cores to the foreign market since 1993, which made it possible to raise the quality level to world standards.

So, what does the use of amorphous and nanocrystalline alloys in SMPS give?

The answer is known only to Specialists who professionally delved into the problem of this issue:

- Improved functional performance;

- Increased efficiency;

- Solving EMC problems;

- Expansion of the temperature range;

- Reduced size and weight;

- Environmentally friendly production.

The area of application of amorphous and nanocrystalline materials is very wide. Below are recommendations for the selection of magnetic cores in relation to the design and manufacture of switching power supplies.

Fig. 1. – Simplified block diagram of the multichannel SMPS АС/DC

Table 1 – Recommended core series

| Application |

Material |

Series designation |

|---|---|---|

|

Common-mode choke L1, L15 |

Nanocrystalline АМАG 200С |

MSFN |

|

Differential choke L2, L12, L13, L14 |

Amorphous АМАG 202 |

MSC |

|

Nanocrystalline АМАG 178N |

MSCN-TH |

|

|

Amorphous pressed (powder) |

АРН |

|

|

Nanocrystalline pressed (powder) |

АРМ |

|

|

Choke of power factor correction L3 |

Nanocrystalline АМАG 200С |

MSC-NGN |

|

Nanocrystalline АМАG 178N |

MSCN-TH |

|

|

Nanocrystalline pressed (powder) |

АРМ |

|

|

Power transformer Тр.с |

Nanocrystalline АМАG 200С |

MSTH-TH |

|

Amorphous АМАG 186 |

MST |

|

|

Nanocrystalline АМАG 178N

(Fly-back transformer)

|

MSCN-TH |

|

|

MagAmp choke (magnetic key) L4, L5 |

Amorphous АМАG 172 |

MSSA |

|

Nanocrystalline АМАG 200 |

MSSN |

|

|

One-turn noise reduction L6…L8 |

Amorphous АМАG 172 |

MSB |

|

Multi turn noise reduction L6…L8 |

Amorphous АМАG 172 |

MSK |

|

Output choke (inductor) L9, L10, L11

|

Amorphous АМАG 202 |

MSC-NGA |

|

Nanocrystalline АМАG 200C |

MSC-NGN |

|

|

Nanocrystalline АМАG 178N |

MSCN-TH |

|

|

Amorphous pressed (powder) |

АРН |

|

|

Nanocrystalline pressed (powder) |

АРМ |

|

|

Current transformer |

Amorphous АМАG 186 |

MST |

|

Control transformer for power semiconductor devices |

Nanocrystalline АМАG 200С Nanocrystalline АМАG 201 |

MSTH-TH |

1. Common Mode / EMI Suppression Chokes (L1, L15)

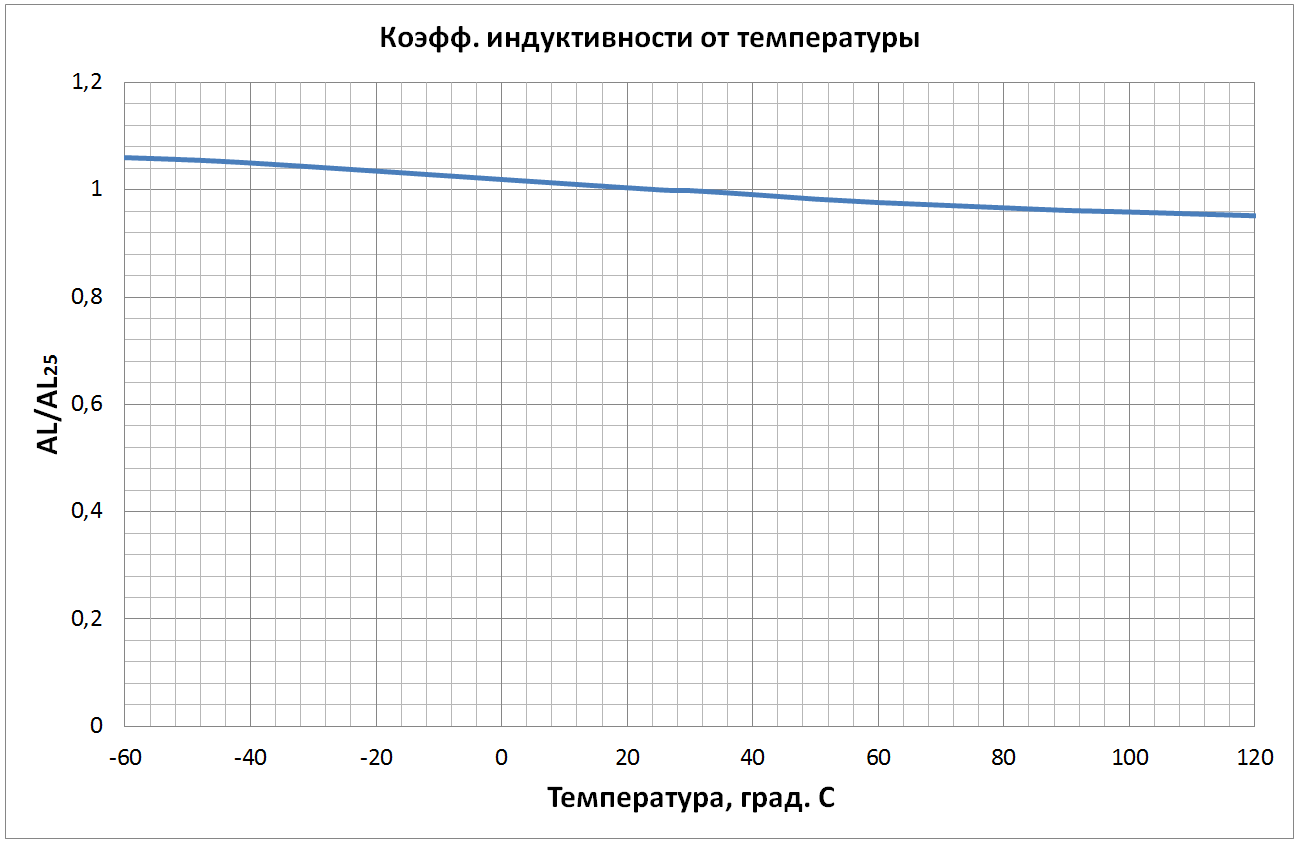

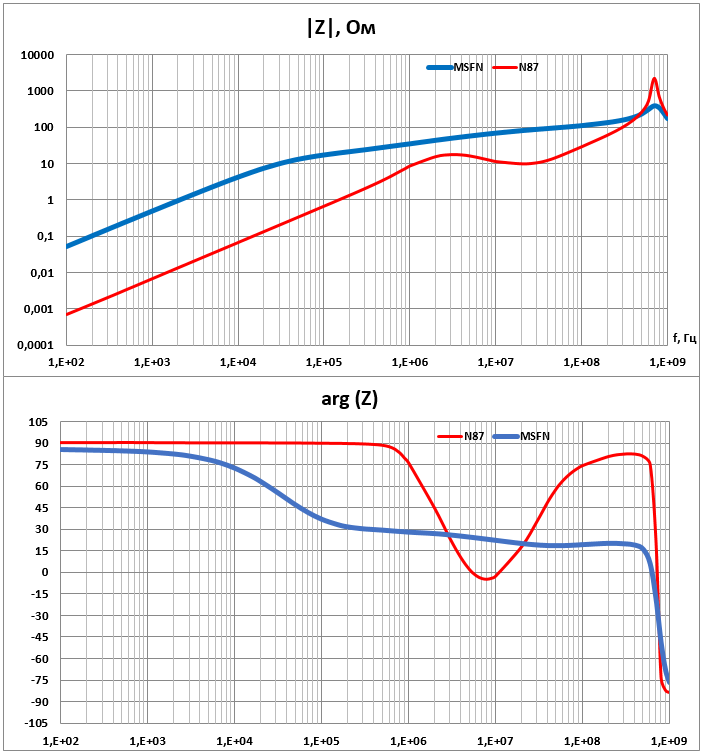

MSFN series from the Fe-based nanocrystalline alloy АМАG 200С is recommended. The alloy is a functional analogue of the materials NANOPERM (Magnetec), VITROPERM (Vacuumschmelze). Saturation flux density 1.16 Т. The temperature range is –60…155°С. Good temperature stability – the change of permeability in a specified range is about 15 %.

The cores of MSFN series are widely used in the common-mode chokes of DS2 and DS3 series.

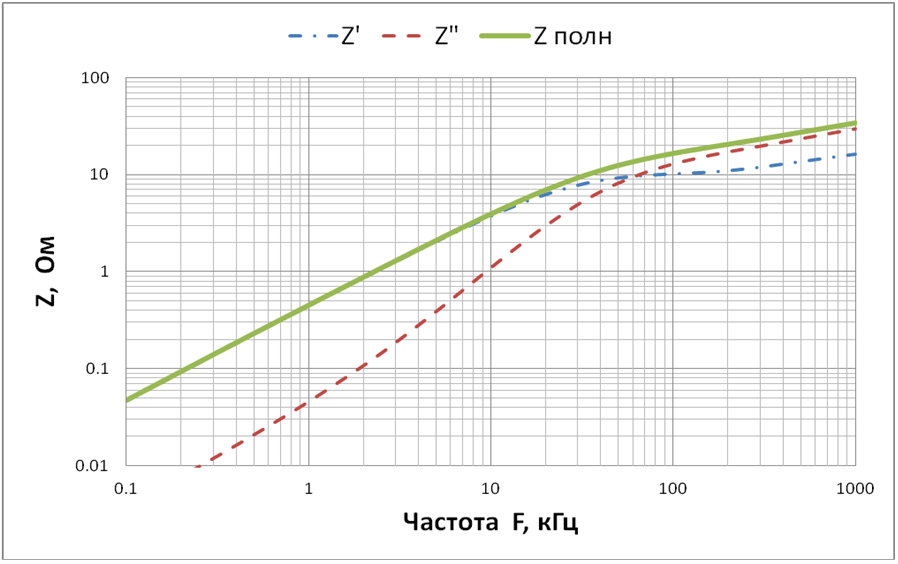

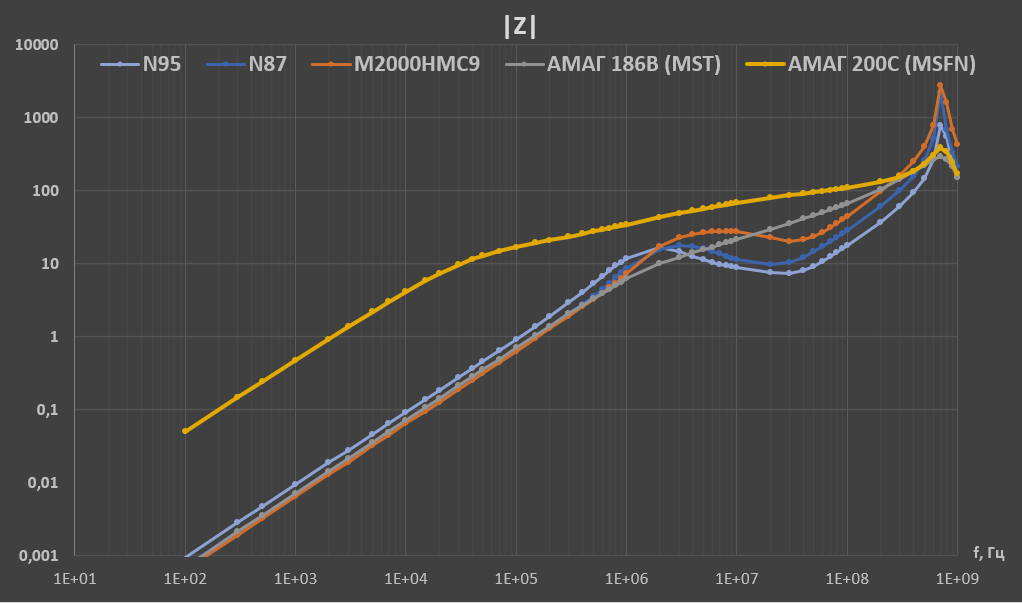

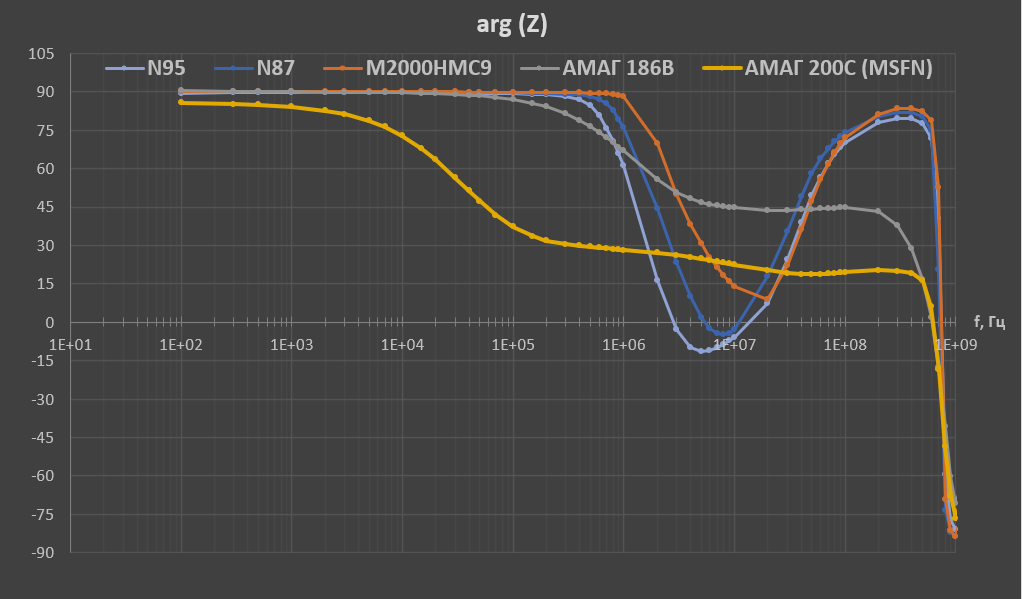

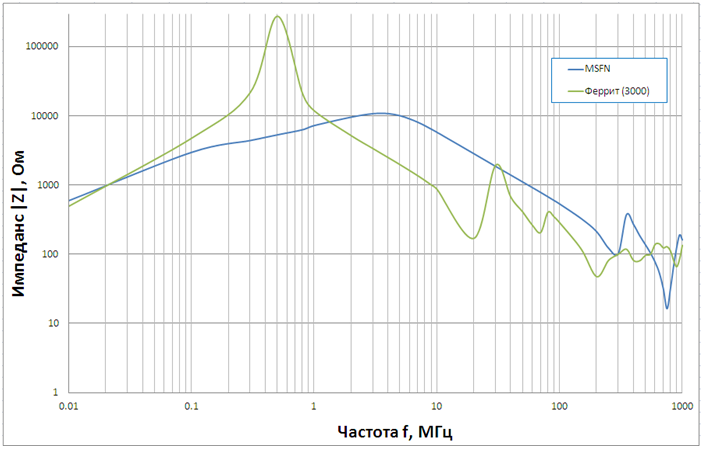

Typical actual initial permeability (µ ') at a frequency of 1 kHz is about 100,000. At frequency of 10 kHz - 85,000. At 100 kHz - 26,500. At 1 MHz - 4100. Permeability decreases monotonically over the entire frequency range. There is no resonance characteristic of ferrites in the 2-4 MHz region with a 1.5-fold increase in the permeability, a phase reversal, and a subsequent rapid decline. The impedance modulus in a single-turn inductor continuously increases monotonically with increasing frequency (Fig. 3). The resonance at 600 MHz is related to the characteristics of the measuring winding (long line). With an increase in the number of turns and, accordingly, an increase in the length of the wire, the resonance shifts to the left. On the basis of the MSFN series, a series of common mode chokes has been developed for single-phase and three-phase networks. Due to the high permeability of the material, the chokes have a 4-5 times smaller number of winding turns relative to their counterparts on ferrite. Typical resonance frequency of chokes is in the region of 1-3 MHz. For ferrite analogs, the resonance frequency is usually 4-5 times lower. For broadband EMC filters, a two-link filter with a small number of turns is recommended.

Fig.3 – Frequency dependence of module and impedance phase for MSFN series compared with ferrite N87 for the toroidal core 30-20-10 mm (one-turn winding, I × w = 10 мA × turn).

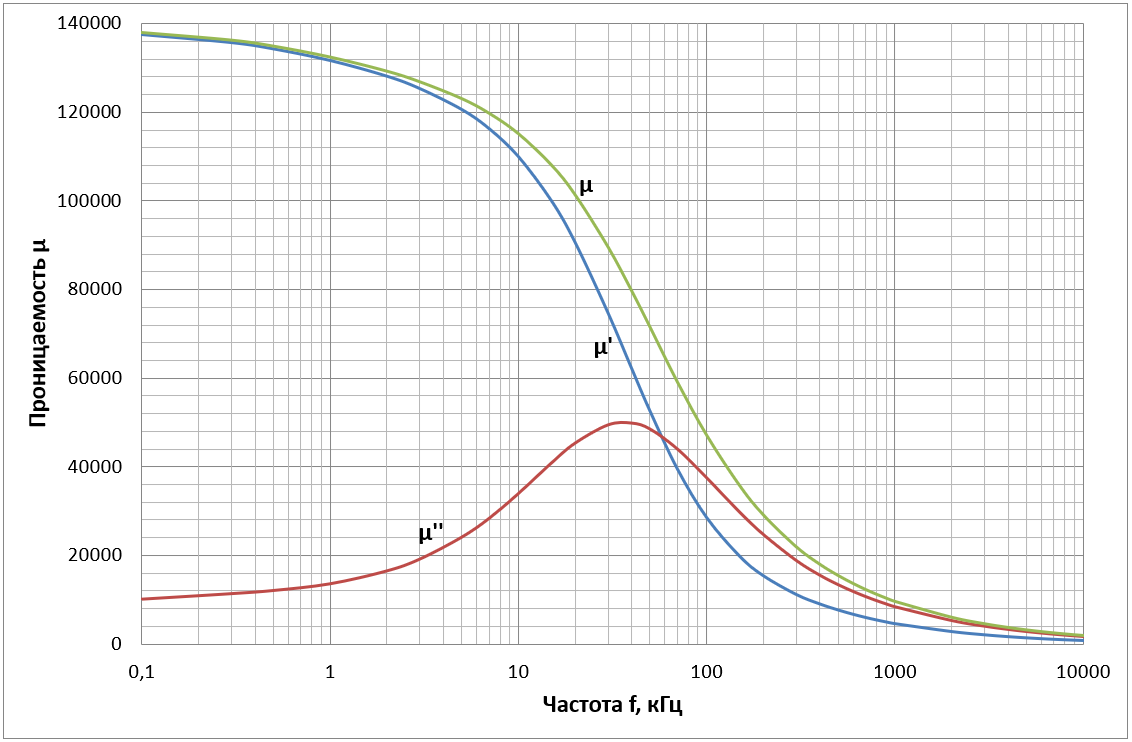

The operation ofthe comon-mode choke based on a nanocrystalline material with high permeability is fundamentally different from the choke from ferrite. At frequencies up to 30 kHz, the real (inductive component of the permeability) µ 'prevails (Fig. 4). At frequency of about 50 kHz, the real and imaginary components are approximately equal. And then the imaginary component µ '', determined by losses, prevails. That is, in the high-frequency region, the choke effectively absorbs the high-frequency interference, converting it into heat.

Figure 5 shows the frequency dependences of the impedance components. In the high-frequency region, the impedance is mainly determined by the imaginary component Z '', i.e. loss resistance.

Fig. 4 – Frequency dependence of permeability for MSFN series (toroid 30-20-10 mm, I × w = 10 мА × turn)

The world leader in the field of amorphous and nanocrystalline materials, the German company Vacuumschmelze, notes this fact [1] as an advantage of the nanocrystalline material Vitroperm (functional analogue of AMAG 200C) when applied to common-mode noise suppression chokes. In the HF region, the ferrite choke works to reflect the interference, and the Vitroperm-based choke works to absorb.

Fig. 6 – Comparison of a module and impedance phase for different materials

Fig. 6 shows the frequency dependences of the module and phase of the impedance of the chokes with a single-turn winding based on various soft magnetic materials. The impedance modulus values are reduced to one standard size of the magnetic core. For three brands of ferrites N87, N95, M2000NMC9, a characteristic resonance with a sharp change in the phase of the impedance appears. In this case, the inductive character of the choke changes to a capacitive one. For amorphous material AMAG 186B (µ = 2200) and nanocrystalline AMAG 200C (MSFN series), no pronounced resonance is manifested. In the low-frequency region, up to 30 kHz, the choke behaves like an ideal inductance (L - circuit), in the high-frequency region it behaves like an RL circuit with a gradual increase in losses and a decrease in inductance. All tested chokes had a second pronounced resonance at the same frequency - 600MHz. As it turned out, this resonance is determined by the length of one turn of the wire, and not by the properties of the material.

Fig. 7. – Frequency dependence of the choke 11 мH for MSFN series (12 turns) and ferrite (70 turns)

Fig.7 shows the dependence of impedance on frequency for the 11mH choke based on the MSFN series and an 11mH choke of the same size based on a ferrite toroid with a permeability of 3000. 12 turns on a nanocrystalline magnetic core and 70 turns on a ferrite are obtained. The number of turns on the ferrite and the length of the wire are 5.5 times larger. In the same ratio the resistance of the windings and the loss in the wire. The ferrite choke has a resonance at frequency of 500 kHz, a nanocrystalline one - at frequency of 3MHz.

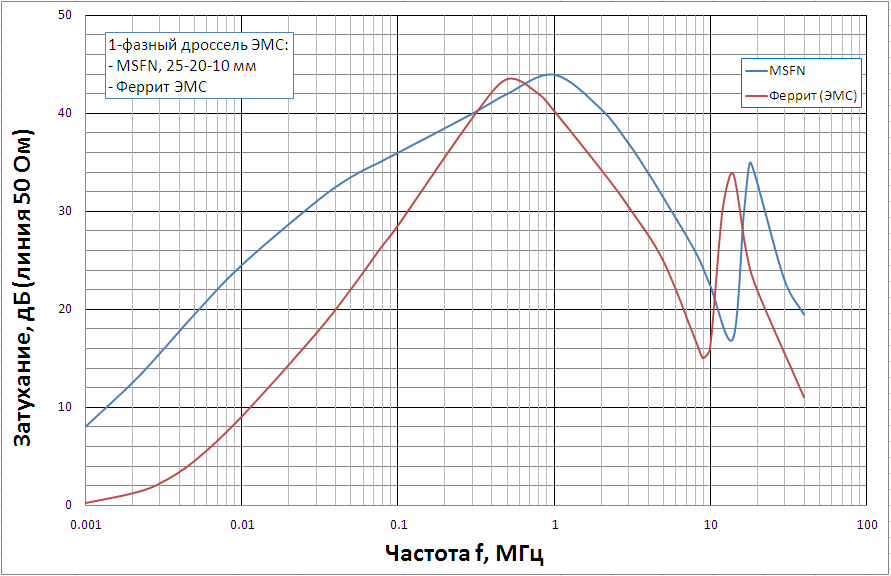

Fig. 8 shows a comparison of the attenuation characteristics in a 50-ohm line for an EMC ferrite-based choke and an MSFN-based choke of similar dimensions. In the low-frequency region, the nanocrystalline choke provides greater attenuation due to the high permeability, and in the high-frequency region, due to the small number of turns and, accordingly, the small wire length.

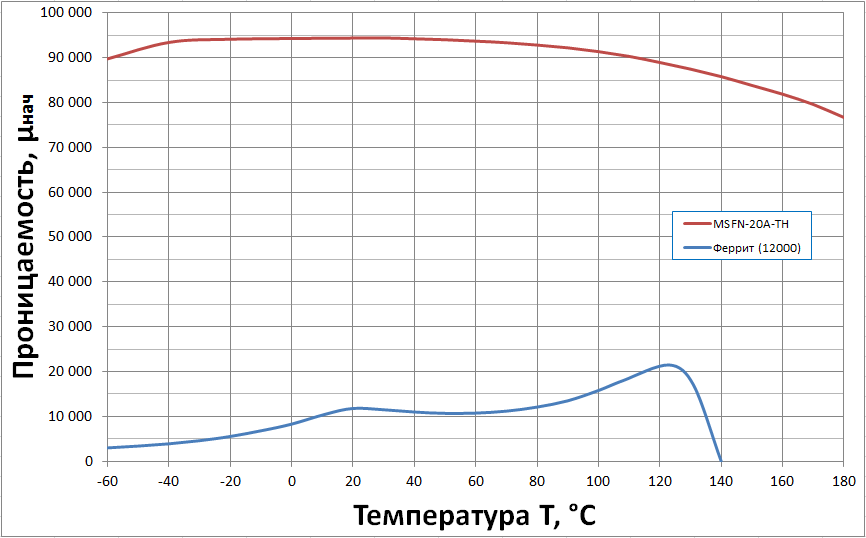

Fig.9 shows the typical temperature dependence for T46 ferrite (data from Epcos manufacturer) with high permeability. Note the sharp temperature dependence of permeability. Change in permeability in the range from –60 to +110 °С by a factor of five. When the temperature exceeds +120 °C, the permeability drops sharply and already by +140 °C it becomes equal to zero. The same graph shows a similar experimental dependence for the MSFN series in the range from –60 to 180 ° С. In the range –60 °С ÷ +155 °С, the change in permeability is only about 15%.

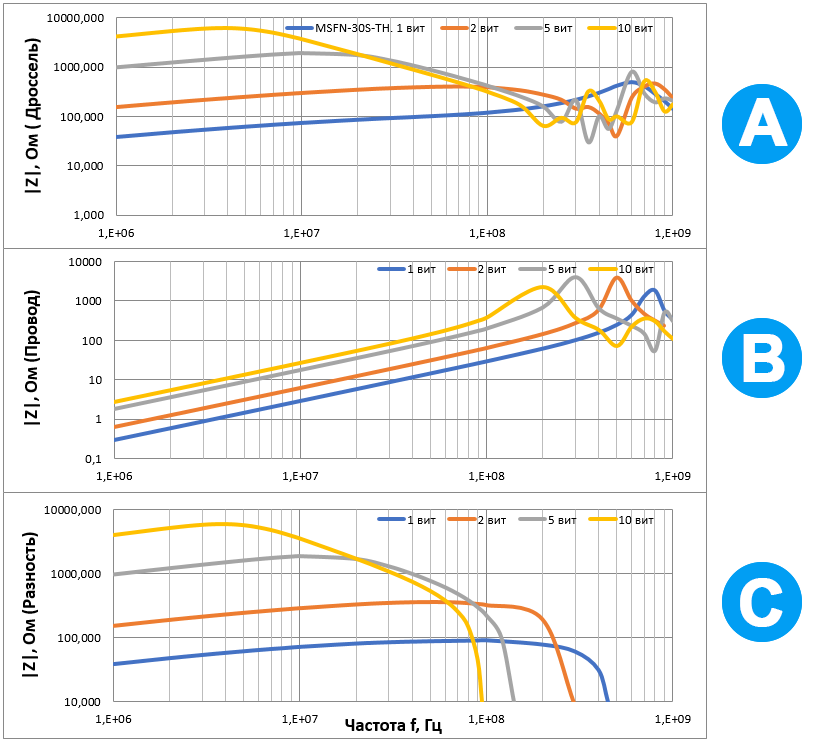

Fig. 10 – а) – Dependence of the choke impedance module on turn number and frequency, в) – impedance of wire, с) – difference of impedance of the choke and wire

Fig. 10 a) shows the dependence of the choke impedance (MSFN-30S-TH) on the turn number and frequency, in Fig. 10 c) - the dependence of the impedance of the wire on the frequency (the wire is wound on an empty container without a core), in Fig. 10 s) - the difference between the impedance of the choke and the wire. This is not entirely correct, since the phase is not taken into account, but it allows us to understand to what frequencies the material retains its magnetic properties. Comparing Fig. 10 a) and Fig. 10 c) one can see that the second resonance is determined by the wire itself, primarily by its length. Moreover, the characteristics of a separate straight wire and a wire wound on an empty container differ insignificantly. From the data obtained, it follows that the limiting frequency of the choke, at which the magnetic material operates, depends on the length of the wire. In this case, for 1 turn, the material works up to 450 MHz, for two - up to 300 MHz, for five - up to 140 MHz, for 10 turns - up to 95 MHz. Moreover, it turned out that the characteristics of the wire depend a bit on the material of the wire, the diameter of the wire, the number of turns and their location on the core, but very much depend on the length. Therefore, for high-frequency filters, it makes no sense to use chokes with a large number of turns and a long wire length, they will not work at frequencies of tens of megahertz. It is more correct to use two chokes with a small number of turns in series.

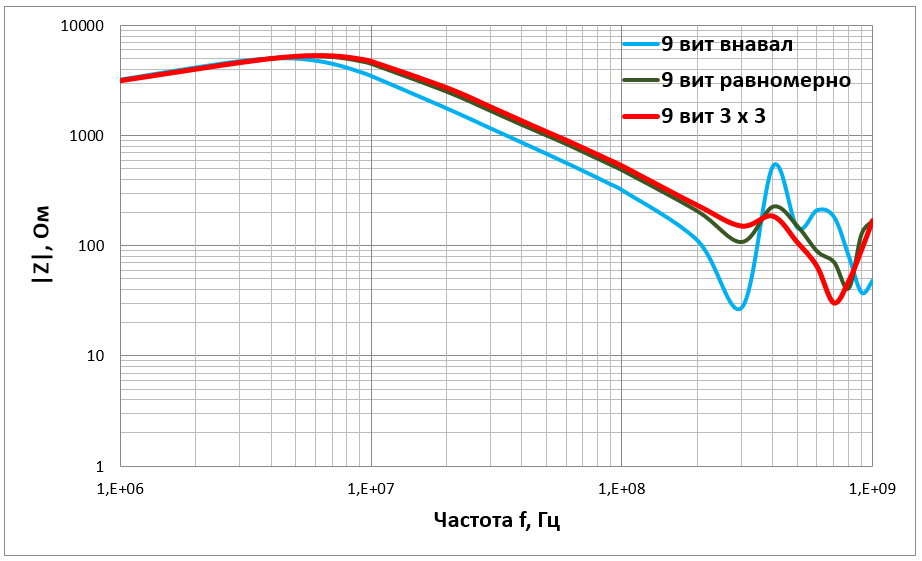

Fig. 11 – Influence of the winding method

Fig. 11 shows the effect of the winding method. The length of the wire and the number of turns are the same. Winding in bulk gives the worst result in terms of impedance value, the lowest frequency of the first resonance and the largest oscillation amplitude | Z | at the point of the second resonance (300 kHz). Uniform winding with spacing of the turns along the core gives an average result. And the best result is sectional winding - 3 sections of 3 turns. Minimization of the winding capacitance shifts the point of the first resonance to the right and reduces the amplitude of oscillation | Z | (reduces the Q factor) at the second resonance point.

Several practical conclusions follow from the above. To shift the resonance of the choke to the right and improve the characteristics of interference suppression, it is rational to:

- use the small sized magnetic cores with the minimal window for winding;

- use thin wire arising from the requirement to permitted overheating;

- use the toroid cores with round cross-section;

- for the ribbon magnetic cores, the use of the cores with a square section is better than with a rectangular one.

2. Differential chokes (L2, L12, L13, L14)

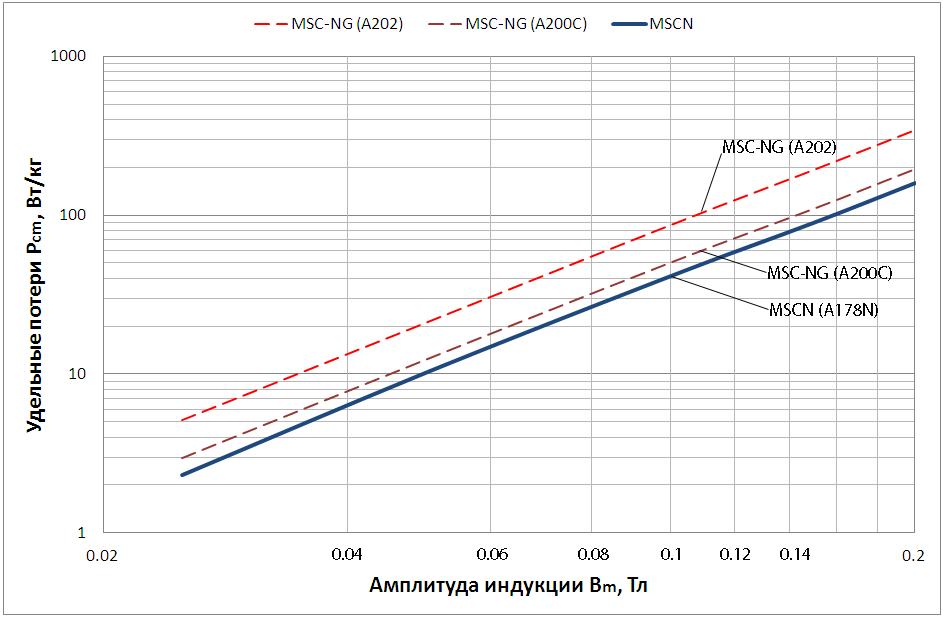

- Small-sized MSC series from the non expensive Fe-based amorphous alloy АМАG 202. With distributed gap resulting from special annealing. Typical permeability is 245. Maximum dc bias field is up to 35 Oe. Saturation flux density is 1.4 Т. Small-sized cores in thin-wall containers from the Al-based alloys. Sizes on outer diameter from 3 to 20 mm.

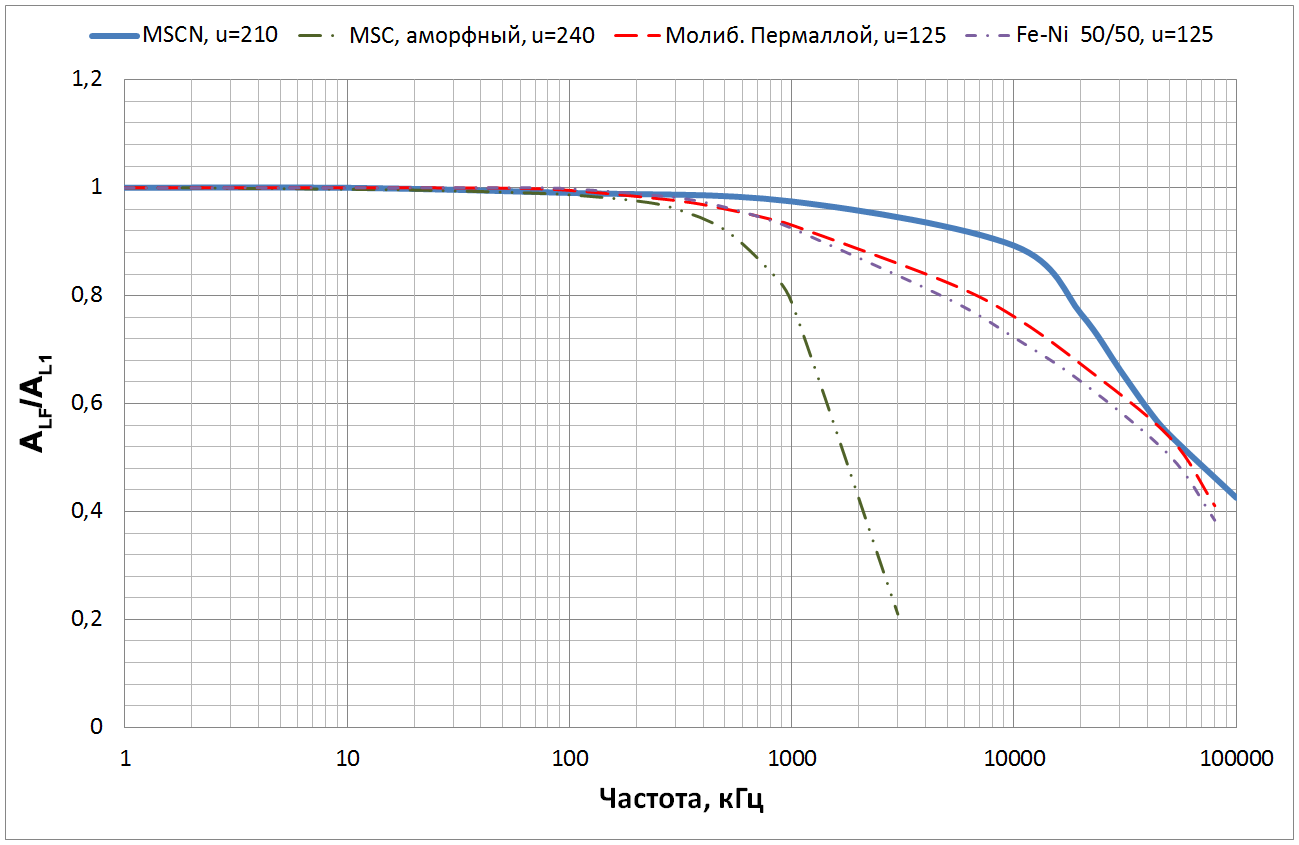

- MSCN series from the new nanocrystalline alloy АМАG 178N. Saturation flux density is 1.05 Т. Typical permeability 210. Perfect frequency characteristics. Fall of permeability at frequency 10 МHz (relatively to 1 кHz) about 10%. Very low losses. Good temperature stability.

- АРН, АРМ series. Not expensive pressed cores (magnetodielectrics) from the pulverized amorphous (Вs = 1.4 Т) and nanocrystalline ribbon (Вs = 1.16 Т) with enamel coating. Produced by a MSTATOR stockholder – Korean company AMOGREENTECH. PC "MSTATOR" is a distributor in RF. Better than the famous materials МП-140, МП-160, High Flux, Kool Mµ, MPP on losses. Permeability range: 26, 60, 75, 90, 125.

3. Choke of power factor corrector L3

- MSC-NGN series. Toroidal magnetic cores with non-magnetic gap from the nanocrystalline alloy АМАG 200C with saturation flux density 1.16 Т. Low loss. Maximum dc bias field is up to 40 Oe.

- MSCN seies. New nanocrystalline alloy АМАГ 178N. Very low losses. Lwer approximately by 30% than of MSC-NGN series. Saturation flux density 1.05 Т. Maximum dc bias field is up to 35 Oe.

- APH, APM series. See clause 2 (differential chokes).

4. Power transformer Tr. c.

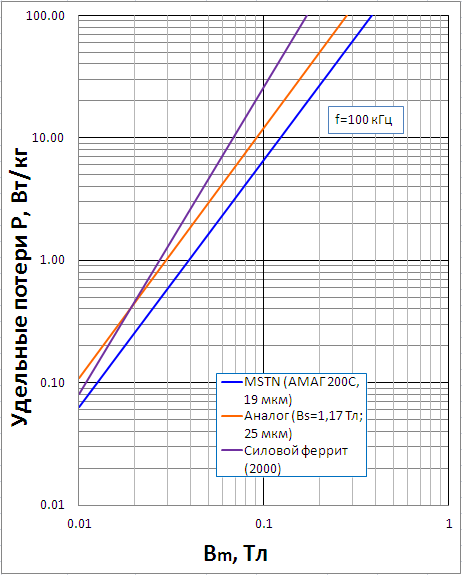

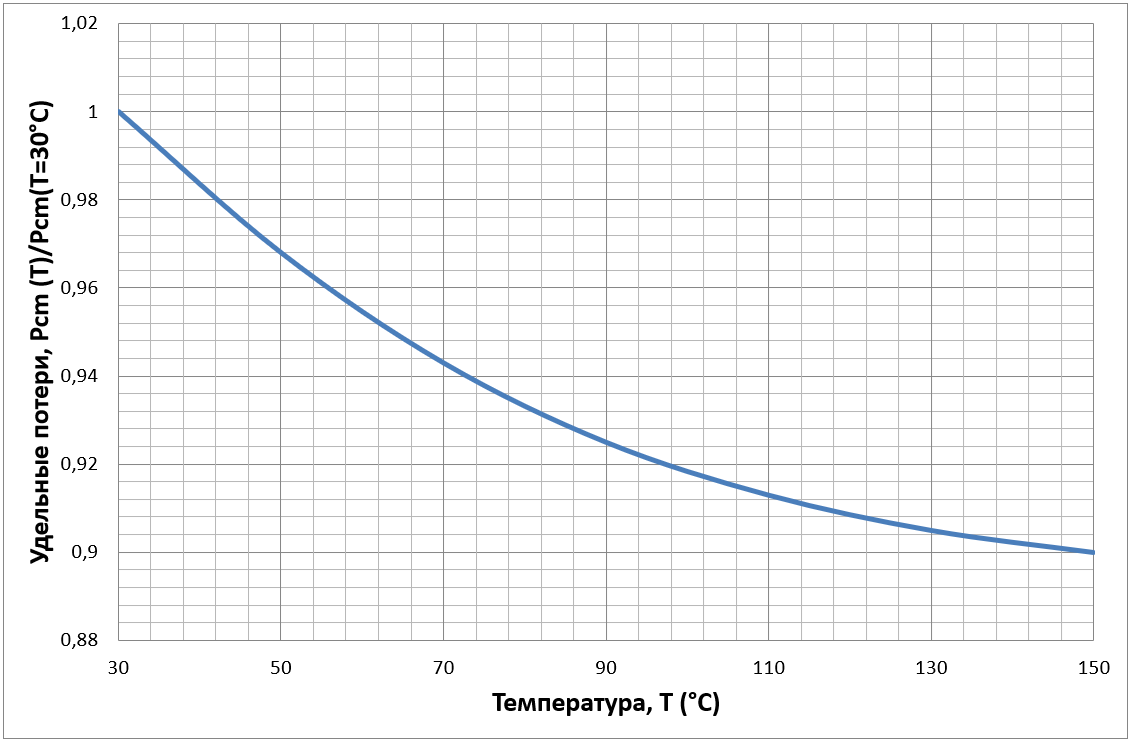

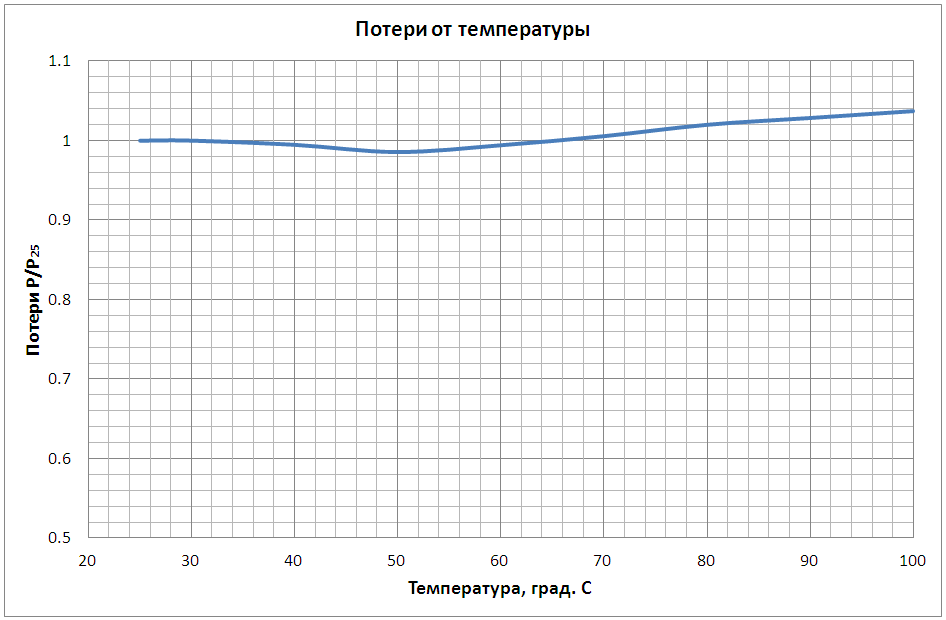

- MSTN series. Nanocrystalline material АМАG 200С with higher permeability and low losses. Improved functional analogue of the famous material FINEMET. Magnetostriction is decreased by 4 times. Special annealing,optimized on loss minimum. Saturation flux density 1.16 Т. Wide temperature range from –60 to 155 °С. Falling loss dependence on temperature. At temperature of 150°С the losses decrease approximately by 10% relatively to 30 °С. Improved linearity of hysteresis loop relatively to MSFN series. Typical permeability µ' at frequency 1 кHz – 65 000, at 100 кHz – 30 000, at 1 МHz – 5000. Fig.16 shows comparison of loss with wound strip similar product of other producer (ribbon thickness 25 μm) and power ferrite wit permeability 2000. Maximum advantage relatively to ferrite is achieved when operating at average conversion frequencies (50-100 кHz) with great amplitude of induction. Typical loss in mode of 100 кHz, 0.3 Т is about 60 W/kg, in mode of 50 кHz, 0.6 Т – 70 W/kg.

- MST series.

Recommended, when use of the material with high permeability is not desirable. Amorphous material АМАГ 186А, В, С. Permeability respectively 3300, 2200, 1400. Saturation flux density respectively: 0.85; 0.9; 1.0 Т. Unique linear hysteresis loop. It is also used in pulse current transformers (SMPS power protection circuits), current transformers in industrial power networks in the presence of a leakage current, in telecommunication systems. Magnetostriction of saturation is near to zero. Good results in step-up pulse transformers with clean short edges. Low losses, weak dependence of permeability on frequency and amplitude of induction are also used in linear power inductors. Alternatively, it is used in resonant circuits.

In EMC filters, linear inductors with low spread and constant permeability allow obtaining a good agreement between practical results and calculated ones and the stability of filter characteristics under various operating conditions.

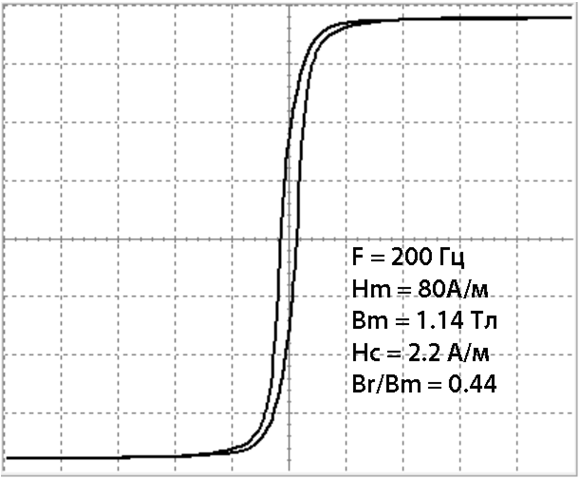

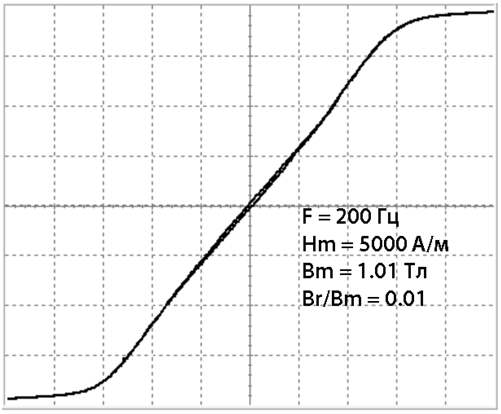

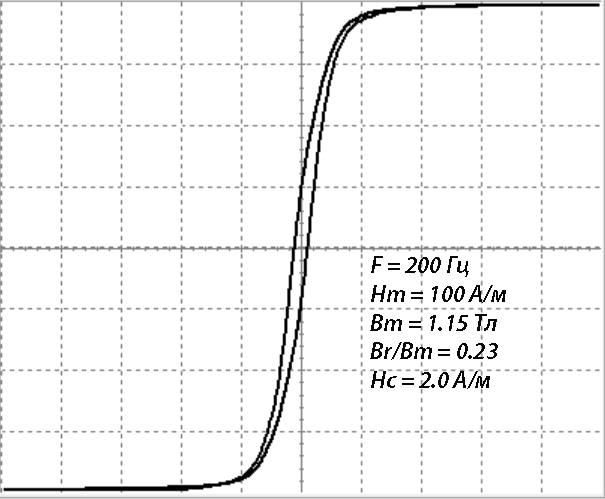

Fig. 18 – Typical hysteresis loop for MST series (АМАG 186)

- MSCN series. Nanocrystalline material АМАG 178N with low permeability (210) and minimal loss. Good alternative to ferrites with gap or magnetodielectrics in the fly-back converters. Due to the lack of gaps, it has an EMC advantage. The magnetic field is concentrated inside the core, does not go out. It has low loss at considerable amplitude of induction. Saturation flux density is 1.05 Т. Linear hysteresis loop, maximum dc bias field is 35 Oe, good temperature stability. Temperature range is from –60 to 155°С. The material itself permits operation at extremely high temperatures to 250 °С. Typical HL – see Fig.10.

5. Magnetic amplifier choke (L4, L5)

Magnetic amplifier chokes are used in multichannel power supplies to organize separate local voltage / current stabilization of each channel. In this case, the voltage in each channel becomes independent of the load of the remaining channels. It becomes possible to protect (stabilize) the output current and the possibility of external independent control of the voltage of each channel using an external analog signal. More details [8].

- MSSA series. MSSA series. Co-based amorphous alloy АМАG 172. Induction 0.6 Т. Rectangular hysteresis loop with ratio Br/Bm not less 0.97 in measuring mode 100 кHz, 80 А/m. Low coercive force, less 17 А/m in measuring mode 100 кHz, 80 А/. Low coercive force secures a small value of control current and low loss in control circuit. Temperature range is from –60 to +100 °С.

- MSSN series. Nanocrystalline material АМАG 200 with annealing in the longitudinal magnetic field. Rectangular hysteresis loop with ratio Br/Bm not less 0.97 in measuring mode 100 кHz, 80 А/m. Coercive force, less 25 А/m in measuring mode 100 кHz, 80 А/m. High flux density (1.16 Т) secures reduction of the coke sizes. Temperature range is from –60 to +155 °С.

6. Noise suppression magnetic cores (L6, L7, L8)

Effectively block the high frequency fluctuations or current surges. Changes the switching behavior, making it "soft", eliminating the cause of EMC interference. An alternative to traditional RC damper connected in parallel with the power diodes. Increase efficiency of the source. Two series of cobalt-based amorphous alloy AMAG 172 are used. More details [9].

- MSB series. One-turn miniature chokes. They are put on the leads of the components. The terminal is a winding. Functional analogs of ferrite beads, but due to their high permeability, they have the best efficiency.

- MSK series. (Spike Killers). Multi-turn chokes. Winding comprises several turns (typically 3-5) by thick wire. Used where it is necessary to have a greater value of the double (total) flux.

7. Power output chokes (inductors) (L9, L10, L11)

- APH, APM series. Inexpensive powder pressed cores based on the pulverized amorphous (APH series) and nanocrystalline (APM series) ribbon. Saturation flux density is respectively 1.5; 1.2 Т. Permeability from the line 26, 60, 75, 90, 125. Higher ultimate dc bias value (loading current). Low loss. They are produced by the stockholder of PC "MSTATOR" ("Amogreentech"). PC "МSTATOR" – is a distributor in Russia.

- MSC-NGA series. A series with non-magnetic gap. Fe-based amorphous alloy similar to famous 2НСР. Saturation flux density 1.4 Т. Average loss but high ultimate dc bias value (to 60Oe, in dependence on permeability).

- MSC-NGN series. Series with non-magnetic gap. Fe-based nanocrystalline alloy. Induction 1.16 Т. Low loss, lower relatively MSC-NGA, ultimate dc bias value to 40 Oe .

- MSC series. Miniature cores from the inexpensive Fe-based amorphous alloy АМАG 202. With distributed gap resulting from special annealing. Typical permeability is 245. Maximum dc bias field is to 35 Oe. Saturation flux density is 1.4 Т. Miniature cores in thin-wall containers from Al-based alloy. Size range on outer diameter is from 3 to 20 mm.

- MSCN series. A new nanocrystalline alloy АМАG 178N. Saturation flux density is 1.05 Т. Typical permeability is 210. Very low loss. Good temperature stability. Maximum dc bias field is to 35 Oe. Wide size range, outer diameter is from 4 to 46 mm.

On the corporate website of PC “MSTATOR” in section "Design Center" there is a set of calculator programs for quick calculation of electromagnetic components according to the given characteristics [10]. In particular, this software allows you to evaluate quickly which series of the magnetic cores is best suited for a specific user task.

In the initial data, you can one by one set each series of magnetic cores from the list, make a calculation and then select the best option.

Литература

- VACUUMSCHMELZE. EMC products based on nanocrystalline VITROPERM // Edition 2016. www.vacuumschmelze.com

- Dmitrikov V.F., Shushpanov D.V. Immunity and electromagnetic compatibility of devices and power supply systems // Hot line – Telecom, 2019.

- Cuellar C., Idir N., Benabou A. High Frequency Behavioral Ring Core Inductor Model // IEEE Transactions on Power Electronics, Volume: 31, Issue: 5, May 2016. С. 3763 – 3772.

- Starodubtsev Yu.N., Belozerov V.Ya. Magnetic properties of the amorphous and nanocrystalline alloys // Ekaterinburg: Publ. house of Ural institute, 2002. page 384.

- Michael E. McHenry, Matthew A. Willard, David E. Laughlin. Amorphous and nanocrystalline materials for applications as soft magnets // Carnegie Mellon University, Pittsburgh, Pennsylvania 15213, USA Received 30 November 1998.

- Starodubtsev Yu.N. Soft magnetic alloys. Encyclopedic Dictionary // Technosphera, 2011. – page 664.

- Dmitrikov V.F., Petrochenko А.Yu., Isaev V.М., Shushpanov D.V. Features of designing network filters for radio interference in a wide frequency range, taking into account the equivalent resistance of capacitors and chokes // /publications

- Fochenkov E.А. Application of the amorphous saturation cores of MSSA series in the multichannel switching power supplies // /publications

- Fochenkov E.А. Application the small sized noise suppression cores from the amorphous metal alloys // /publications

- Fochenkov E.А. Amorphous and nanocrystalline alloys in switching power supplies. Programs of winding components calculation // /publications

E. Fochenkov, edf01@yandex.ru.