MSTN series

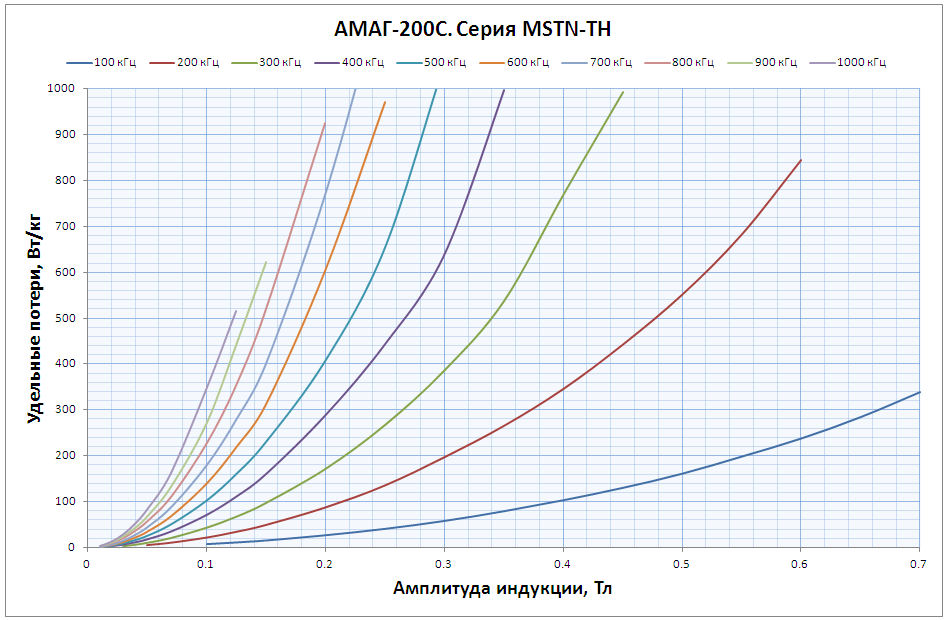

Toroidal cores of the MSTN series (KVSU.684459.090 TU) are made of a thin (18 ± 2 μm) nanocrystalline ribbon AMAG 200C with annealing in a strong transverse field.

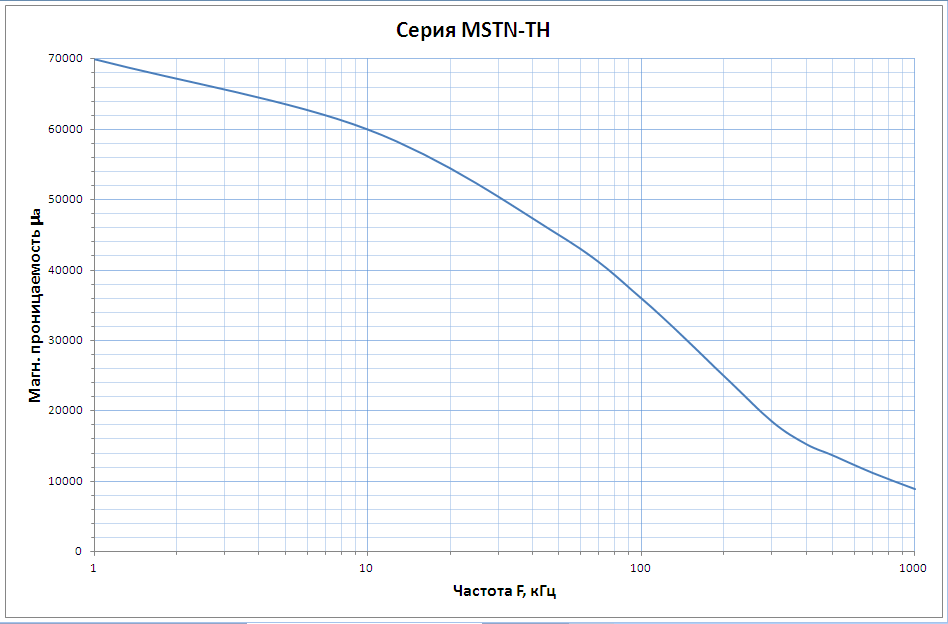

• They are characterized by low losses, high saturation induction, high operating temperature (up to +155 °C), high magnetic permeability.

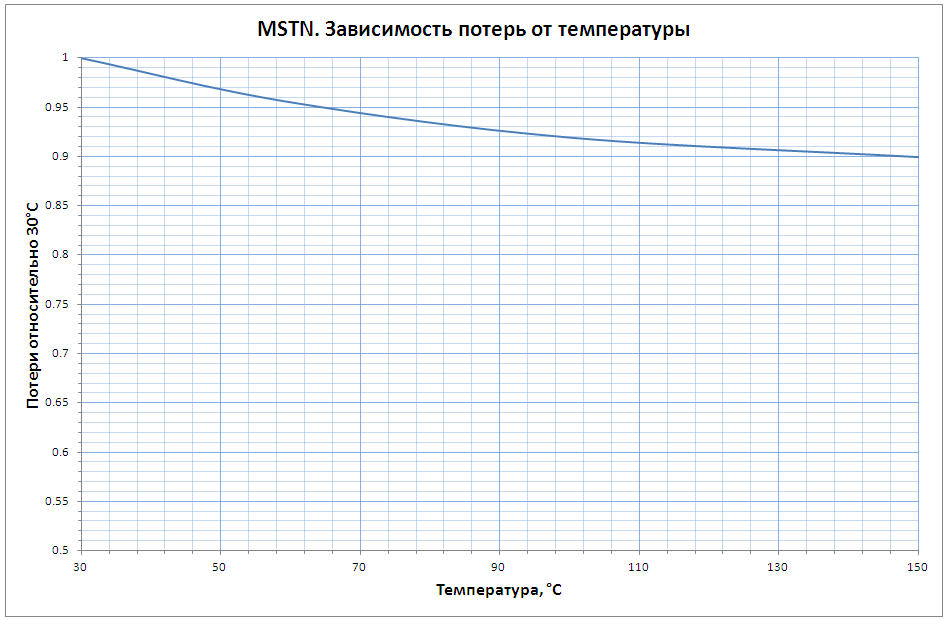

• Cores have a negative temperature coefficient of loss, which ensures the stabilization of the transformer temperature.

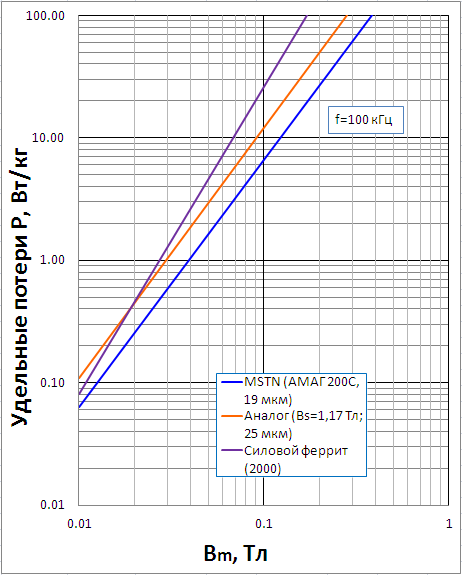

• The use of a thin ribbons and a special loss-optimized annealing ensure in this series the value of losses on the level of the best amorphous cobalt-based alloys.

The MSTN series is designed for use in power transformers of pulse converters at frequencies up to 1 MHz. High induction coupled with low loss results in few turns and size reduction. High permeability ensures good electromagnetic coupling of the windings and low no-load current.

Replacing ferrites with the MSTN series:

- increases the efficiency of the transformer;

- reduces idle current and overheating;

- reduces size;

- reduces the level of electromagnetic interference of the power supply;

- expands the temperature range.

Especially effective for converters with an output power of more than 1 kW, as well as for harsh operating conditions.

They are a good alternative to known materials:

N87, N95, FINEMET, VITROPERM 500F, VITROPERM800, NANOPERM, 1K107, 5БДСР, ГМ414.