MSSA series

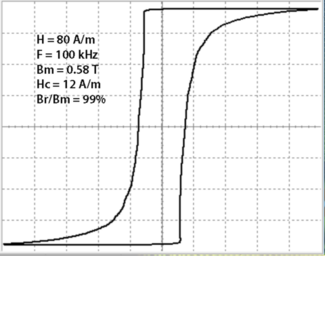

Toroidal saturation cores with a rectangular hysteresis loop, made from a thin (18–20 μm) amorphous ribbon AMAG 172 based on cobalt, are traditionally considered the best for use in magnetic amplifier chokes (AM). MU technology is synonymous with reliability in modern switching power supplies.

In most multichannel power supplies, only one output voltage is regulated by a common feedback loop from the output of this channel to the PWM regulator. The dynamic properties of the remaining channels are much worse, they are dependent on each other. For independent stabilization of the channel voltage, various adjustment methods are additionally used. Conventional linear regulators reduce efficiency and are only acceptable for low output currents. Electronic governors are more efficient, but also more bulky due to the larger number of components and are therefore less reliable and more expensive.

The use of a magnetic amplifier is a cheap, effective and reliable solution to these problems. It easily achieves efficiency levels of more than 90% at switching frequencies up to 300 kHz, contributing to the miniaturization of equipment.